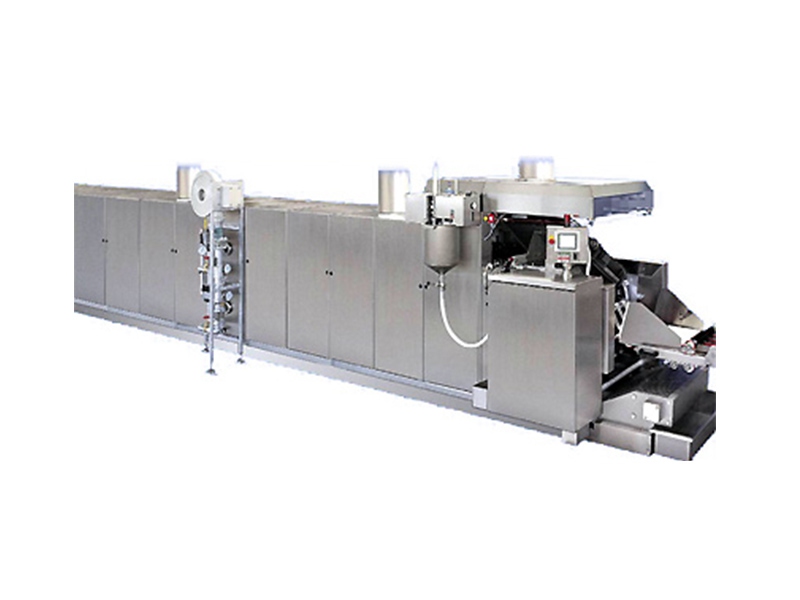

- A machine designed to produce wafer sheets.

- It can be manufactured with 36, 40, 60 or 83 plates with size of 350x500 and 290x470 mm.

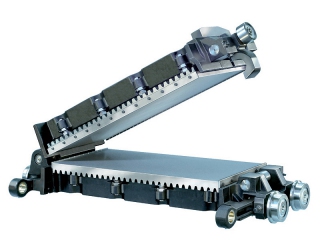

- Carrying trolleys are specially designed.

- Plate’s surface pattern can be manufactured plane or figured water with desired size according to requirement of a customer.

- Automatic sheet taking.

- Chrome-nickel outer surface.

- Solid main structure.

- Inner cabin lighting.

- Lower cleaning knives with chain system.

- Wafer plate cleaning brushes.

- Energy-saving over heat insulation.

- All lids are easily opened.

- Pneumatic back tension system.

- Main drive with frequency-controlled reduction system.

- Manual turning in case of power interruption.

- Production of flat and hollow wafer sheets.

- High quality cast plates and chrome coated surface.

- Easy adjustment of wafer sheets’ thickness.

- Heat-resistant grease and bearings.

- All control parts are placed in main power panel.

- Dough drip prevention system thanks to crawler pump.

- Frequency-controlled dough adjustment.

- Plate numbers for easy marking of wafer sheets.

- Easy maintenance and lubrication.

Heating system

- Suitable for propane or methane gas.

- Gas - air mixing adjustment and safety equipments are available.

- Automatic heat adjustment control.

- Full automatic firing.

- Automatic cutting at low and high gas pressure during power interruption.

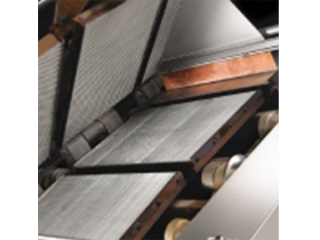

- Easily adjustable triangle baking ovens.

- Exhaust gas eliminating fan within oven.

- Contact-free plate surface temperature measuring.

- Separate adjustment of lower and upper ovens.

- Color PLC touch display.